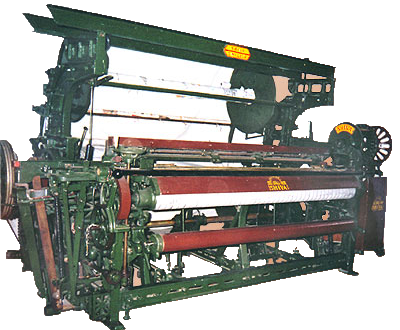

Terry Towel Automatic

Loom 72"

RAMING: Deeper frame with double top rail of M.S. channel

suitable to mount shah cam side dobby on drive side (L.H.) top rail bracket

to mount positive let off motion (pile beam).

DRIVE: Individual con clutch drive with 3 groove loom

pulley to suit (‘A’ Section Belt) crank shaft forged out of

50m/m tested steel. One piece having 3” throw, Band Brake.

Crank & Tappet wheel of higher grade material of machined cut teeth.

TAKE UP: 7 Wheel pickles Take-Up motion with all M/c’s

cut teeth including ratchet wheel, temple ring roller to catch selvege

rest 5 rings of nylon, RH temple provided with cutter.

WORP STOP: 4 Bank sliding type for bottom beam.

PICKING: Side lever under picking system with chilled

picking nose & hardened picking bowl with bush, picking stick &

side levers provded of laminated wood, Buffers both sides provided of

special compressed leather.

LET OFF BOTTOM BEAM: Fully positive let off motion with

parabola cam for regulating the let off with the beam dia through beam

feeler roller, Let off provided with two rollers. (Plated) of 3 ½”

& 4/2” dia on a extended bracket. Bottom beam of 4 3/8”

dia with 20” dia beam flange.

PILE BEAM LET OFF: Fully positive let off motion mounted

on top rail side brackets, with beam feeler roller to work with beam dia,

let off gears machined cut teeth & spring loaded band brake. 2 Nos

plated tension rollers, to work with warp tension, 4 3/8” warp beam

with 26” dia M.S. beam flanger.

BEAT UP SLEY: Loose reed system sley made on Angle iron

with C.I. race ends, special type M.S. reed cap provided with G. Metal

bearings for free movement of reed every loose pick . Sley to suit 390x45x34

m/m & 90” Shuttle.

TERRY MOTION: Special terry cam provided on counter

shaft with gear ratio 2x1 i.e. 2 pack loose one pick fast. For formation

of pile, Stop rod of 1 1/8” dia is conncted through lever with the

terry cam to operate reed movement pile hight can be regulated through

lever, Handle is provided for dis- connecting the terry motion.

DUCK BILL HITTERS ARE PROVIDED OF STEEL.

WEFT FORK MOTION & FEELER: Side weft fork motion

provided shuttle weft feeler motion to operate battery motion on bunch.

BATTERY: Rotary battery (cop change motion) to operate

through weft feeler. To suit 190m/m bobbin with ring of 27m/m dia.

END CUTTER IS PROVIDED TO CUT & HOLD THE OUT GOING WEFT,

NOTE: SHEDDING BY SIDE DOBBY AS SUCH NO SHEEDING TAPPET

ARE PROVIDED .

|