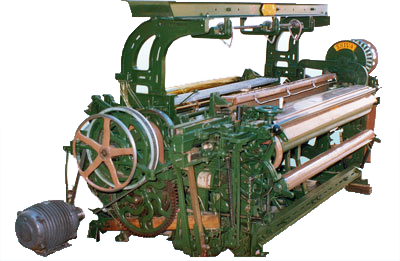

Automatic Loom 72"

FRAMING: Built on heavy duty graded casting with all

framing members of cast iron to avoid vibration , with double top rail

of M.S channel to suit all types dobby mounting, gun metal , sleev for

tappet shaft and gun metal bearing for crank shaft provided in the main

frame.

DRIVE: Individual drive with cone clutch pulley 3 groove

, band brake , crank shaft is forged out of 50 MM tested steel with 3”

throw , crank wheel in two parts of 4 DP tooth 36 theeth, v groove pulley

provided with gun metal sleeve for longer life, oil dampers of SGI body

for absorbing the bang of impact, dagger shaft with carbon steel daggers

duly hardended fitted, dagger piece of special steel duly hardended fitted.

SHEDDING: Tappet Shaft of 13/4” DIA of tested

steel fitted with 80 degree dwell cam shedding with heald shaft; tappet

wheel of 72 teeth of 4 DP stronger teeth.

TAKE UP: Seven Wheel pickles take up motion with machiuned

gears: pinions , ratched wheel , twitch roller with left hand and right

hand threads to expand the cloth, taking up catch of SG iron, stronger

temple bar supported by strong spring, easy sliding on shuttle trap, 3

X10 ring temple , RH box fitted with continous cutter operated by sley.

Spear handle is supplied for stopping the loom.

WARP STOP : Six bank warp stop motion, sliding type,

driving lever, link etc are made out of SGI, bridge bars and round bars

are plated.

PICKING : Side lever, picking with loose pickers, picking

plates are provided with machined serrations for keeping the picking bowl

position firm, no chance of slippage, side levers and picking stick are

of laminated wood, picking nose are having chilled hard surface and picking

bowl of carbon steel hardened for longer life.

LET OFF: Fully positive let off motion, controlling

the speed of Beam pipe through beam feeler which regulate the speed of

the beam through gears/ levers/ parabola curve cam. Special arrangement

of sector brake is provided for mainting the tension of the warp, weight

lever shaft wearing provided with nylon liner, beam flange of 24”

DIA, back roller 4.5” DIA and easing roller of 3.5” DIA supplied

with double easying cams.

BEAT UP: Sley made on one piece angle with 1”

thick shisham wood race board and race end of cast iron on both ends,

Box front made out of SG iron, with double swell and swell reliving motion

for better checking of shuttle, swell bushes are provided of olit (G.M)

material to work without oiling, crank arm fitted with hardened bush and

sley sword pin, Gun metal bearing on crank shaft end, sley sword etc are

of graded casting, reed cap of mild steel for easy Alignment of reed line

provided with shuttle guard.

SHUTTLE SIZE: 390X45X34X32X90 DEGREES

PIRN: 190X3 RINGS 27 DIA

FEELING: Side weft fork system is provided in an enclosed

Box with MCI weft fork slide, weft fork holder ETC, Shuttle feeler of

SG iron TIP is provided.

BATTERY: COP change motion is operated through cam on

weft fork hammer, Bobbin disk is provided with nylon clip in place of

cast iron, transfer hammer, feed pawl, hold back pawl, bobbin support

and latch provided of SGI for longer life.

END CUTTER AND WEFT FEELER: Weft feeler is provide to

operate battery on bunch, 5 blade end cutter is provide of improved design

of hardened blades to hold and cut the out going weft.

NOTE:

- ONE SET OF BEAM PIPE WITH 24” DIA C.I FLANGES SUPPLIED WITH

LOOM.

- ONE CLOTH ROLLER WILL BE SUPPLIED WITH THE LOOM.

- THE LOOMS ARE SUPPLIED WITHOUT WEAVING ACCESSORIES, LOOM DRIVING MOTORS,

STARTERS, AND RAILS ETC.

THE FOLLOWING MOTION CAN BE SUPPLIED AT EXTRA COST WITH THE LOOM

- CENTRE WEFT FORK MOTION.

- SPACER BRACKET TO RAISE TOP RAIL CHANNEL FOR SHAH SIDE DOBBY.

- UNIVERSAL MOTION 2X1,2X2,3X1,4X1,WITH ALL PARTS INCLUDING SPRING TOP

MOTION MOTION AND SELVEGE MOTION.

- LET OFF MOTION OF EXTENDED BRACKET.

- ERRECTION GUAGE BOX.

WE CAN MANUFACTURE LOOM ON DEEPER FRAME TO ACCOMMODATE UP TO 16 HEALD

FRAME |